Performance

- The engine took quite a while to bed in properly, I

think due to the new rings which had to seat

- into the old cylinder wall profiles as it had not been

re-bored, just lightly honed. Having now done

- around 12,000 miles the acid test was a run on a

rolling road.

- The engine had been re-assembled to its standard

format with no porting and original injectors.

- In preparation for some work in this area I wanted to

know how the engine was performing now,

- so that I could assess whether or not the extra work

made any real improvement.

- It should be noted however that at this stage the mods

so far are:-

-

- 1. Chip (Marshy type II, if you're a member of

the Autobahnstormers you'll know what this is all about,

- otherwise join up to find out)

-

- 2. Modified Scorpion Exhaust.

-

- 3. K&N air filter.

4. Extra 1 1/2" dia hole into air box, fed air

from same place as existing intake trumpet.

- 5. Cats replaced with straight through silencers.

-

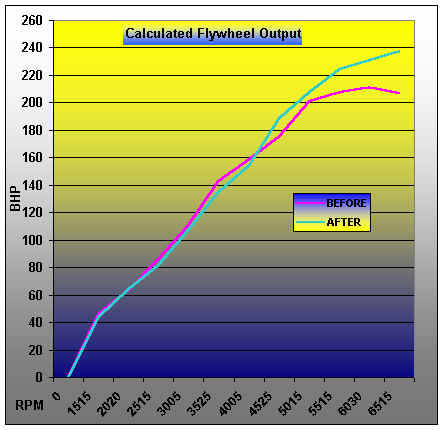

- The test was carried out 3/11/00 at S.A.S Performance

in Aldershot Hants.

- They have a new rolling road system capable of testing

up to 1000bhp including 4 wheel drive vehicles.

- The bottom line max ouput was measured at 212.0bhp to DIN 70020

- (this std takes into account variables such as

temperature/air pressure/humidity etc. of which air temp 16degC,

- Air pressure 981mbar, oil temp 88degC) The standard

book quoted figure is 204bhp.

-

-

- The left hand scale is bhp and the right side is torque

(lbf/ft)

-

- I am quite pleased with the result, the fueling they said was

spot on.

The work which I want to do next is:-

1. Injector clean

2. Match inlet ports and fuel injector manifold and inlet

manifold.

3. Slightly re-profile area just in front of the injector

nozzle, (cylinder head inlet work.)

4. RB stainless steel back box and stainless steel mid boxes

(all straight through).

5. New airflow meter (this was unexpected, but,cured regular

shorts bursts of missfire )

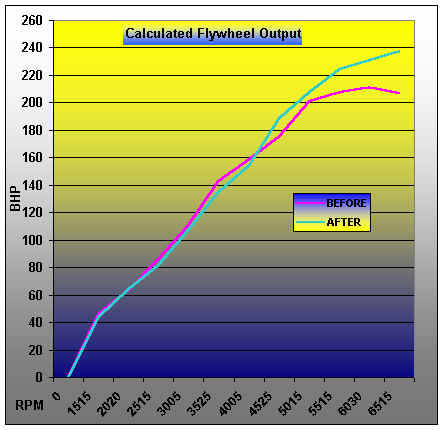

- 26th January I visited SAS once more. The results

below clearly show an improvement overall.

- Interestingly there is a slight drop in power around

2500 - 4500 rpm although the car actually feels

- stronger when driving. The peek calculated power was

measured at 238BHP to DIN 70020

- Air presseure was 984mbar and air temp was 15degC,

pretty much the same as previous run.

-

- A very pleasing result justifying the work that I've done so

far.

- Will Reeve also

attended the dyno and ran his car just after mine,

- this gave me the opportunity to remove the exhaust restictor

plates

- that were located at the engine end of the cat replacement

silencers.

- With previous trial and error research it was found

neccessary to

- replace some of the back pressure in order to get the car to

"feel right".

- Having removed the plates and doing another dyno run, the

difference

- was quite suprising and obviously worse ! The explaination

for this I have

- "borrowed" from Will:-

-

- Now the cat pipes and restrictors: Rich ran his car up

first, recording both

a continuous and then a discrete point power run. The car was fitted with

restrictor plates. This yielded good results with his engine sounding

smooth, quite and the figures bearing this out.

He then went home and removed the plates, replacing them with standard

gaskets. Back at the ‘road the operator reported it was impossible to

measure the discrete points run, during the run, apparently the engine

wouldn’t hold the rpm at open throttle when the ‘road was loading the engine

to measure the torque. The engine was running lean (according to the exhaust

gas analyser which was in use).

Conclusion being that restrictor plates, do just that and restrict the

breathing of the engine, removing the restrictor plates allows more out of

engine for a given time and hence more air into the engine, which isn’t

being met with more fuel, result weaker mixture.

Arrrrr. What about the ECU and the lambda sensor you ask. Well load and

hence fuelling is determined mainly by the AFM (air flow meter) which will

be fully open at much above 4,000rpm and so offers no input to the ECU with

regards air intake, the lambda only works in closed loop mode at part

throttle and idle so at wide open throttle the ECU runs open loop. Hence it

- uses maps only folks and the maps weren’t meant to

fuel an engine with

Richards free flowing exhaust and his inlet manifold tweaks, hence

under-fuelling. That's the general idea anyway.

My car is still running Walker mid boxes which offer some restriction of the

exhaust, but one would assume the problem is worse with a BB head and free

exhaust, and even worse with a MAF (mass air-flow meter conversion), and

free flowing exhaust!

What we are doing? Well we have an air-fuel ratio meter, but unfortunately

it doesn’t like running on the same lambda sensor as the ECU, or rather it

doesn’t mind but the ECU does! I plan to persuade rich to weld an additional

boss into the down pipe and fit another lambda sensor for monitoring

purposes.

The rolling road operator estimated that we need 2 to 3% more fuel above

3,000rpm at wide open throttle, so that’s a starting point. He suggested we

use the air-fuel meter to get the mixture spot on (rich of stoichiometric).

At low rpm and load when the AFM is working within it’s operating range, the

ECU will fuel correctly as it will measure the additional air intake, and

fuel correctly. Hence what I always feel, that part throttle “urge” seems

stronger than full throttle “urge”. So it would seem the backpressure from

restrictor plates = bad, but good if you don’t adjust the maps to enrich WOT

situations.

It looks like a full RB stainless straight through exhaust system (cat pods,

twin mid’s, and back box) needs remapped wide open throttle maps to reap the

full benefits of it’s free flowing design, for the time being restrictor

plates will emulate the cats well enough to keep the fuelling correct. I

think most of you run this way anyway and have walker/Vx back boxes as well.

Fuel Consumption

- It would be natural to think that an increase in performance

would increase fuel consumption,

- this is true to a certain extent in that more power needs

more fuel to be burnt and yes the potential

- to burn more fuel is certainly there. However, with the fuel

now being burnt more efficiently the increase

- in performance at light throttle application has actually

improved MPG's.

-

- 2 weeks ago I installed a Kenlowe block heater. I ran the car

for 3 days to and from work with the engine

- being warmed up before the trip to work but not on the way

home. My journey to work involves 3 miles

- urban, 14 miles motorway and 3 miles urban, the same for

return home. Speed was kept between

- 55 - 60mph, air temp averaged 3 - 5degC.The car achieved

36mpg as an average for the 3 days. I have

- never seen this kind of return before, especially during

winter. The summer figures will be interesting.

-

- Update 31/3/01

- Now with extra lambda installed and connected to a fuel meter

we are starting to try different wot map

- settings. I have removed the restrictor plates and have

been running a richer wot map for a while.

- Checking mpg's over same 3 day period with hot one way

starts have produced 36.5mpg overall average.

- A trip to London along M3 from Farnborough re-setting the

comp after getting up to speed (60mph)

- produced 46.5mpg at the end of the motorway. Previous best

was around 41

-

-